coal mill operational problems

Research on early fault warning system of coal mills based

2019year9month9day This article uses the thermodynamic mechanism of the coal mill as a guide to determine the characteristic parameters that characterize the operation condition of

Үйлчилгээ

Research on fault diagnosis of coal mill system based on the

2020year9month1day Yuguang Niu a , Yaokui Gao a , Dongming Zhang b Add to Mendeley https://doi/10.1016/j.measurement.2020.107864 Get rights and content • A fault

Үйлчилгээ

A unified thermo-mechanical model for coal mill operation

2015year11month1day Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper,

Үйлчилгээ

Modeling of Coal Mill System Used for Fault Simulation

2020year4month7day Abstract Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants. The traditional data-driven fault diagnosis methods

Үйлчилгээ

Coal Mill - an overview ScienceDirect Topics

Operating data from a coal mill is used to compare the fault detection observer-based method and PCA/PLS models based approach. There are 13 process measurements

Үйлчилгээ

Review of control and fault diagnosis methods applied to coal mills ...

2015year8month1day In this paper, a review of researches done on the mill control and methods employed for fault diagnosis of coal mills is provided, with the aim of improving

Үйлчилгээ

Energies Free Full-Text Fault Diagnosis of Coal

2022year7month26day The coal mill faults, such as abnormal loading and mill vibration, etc., increase the unit consumption of coal pulverizing, and the output of grinding coal can not be guaranteed, which has a negative

Үйлчилгээ

Detection of Malfunctions and Abnormal Working

2018year4month19day output parameters of vertical roller coal mill (the pressure drop over the mill, power consumed by the mill and outlet temperature) models have been developed

Үйлчилгээ

Common Problems And Solutions In The Operation Of Coal Mills - Gravel Mill

2022year6month20day 1. The sound of the mill is high and crisp. 2. The grinding current becomes smaller. 3. The pressure difference between the grinding head and the grinding tail

Үйлчилгээ

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018year1month1day The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass ...

Үйлчилгээ

Review on vertical roller mill in cement industry its

2021year1month1day Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: ... There are many explanations for issues such as cost, operation, installation cost, maintenance cost, ease of maintenance, product quality and expertise. ... Operation • Mill Gas Flow - The three roles of the gas flow in the Vertical Roller Mill are: Material drying ...

Үйлчилгээ

Operational parameters affecting the vertical roller mill

2017year4month1day A cement Vertical Roller Mill modeling based on the number of breakages. Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energy-intensive grinding

Үйлчилгээ

Pulverizer failure cause analysis. Final report - OSTI.GOV

This report contains the results of a 16 month study to examine the problem of pulverizer outages and to identify root cause failure modes for the major mill types currently in service. A data base of 469 pulverizers, the majority larger than 40 tons/hr coal capacity, was compiled by surveying the utilities with coal fired boilers in this ...

Үйлчилгээ

Pulverizer Plant OM Aspects

2013year12month6day Mill operational issues Constructional features and maintenance Performance issues and case studies Contents 2 . 3 . The Three Ts One S Practice ... Maximum mill Capacity vs coal moisture at coal HGI 100-110 and PF Fineness of 70 % passing through 200 Mesh 35.00 36.00 37.00 38.00 39.00 40.00

Үйлчилгээ

(PDF) An investigation of performance characteristics and

2020year8month12day In this study, a new method of construction of the coal mill health indicator (HI) is proposed, and the operation condition monitoring approaches of the device are designed based on the HI value.

Үйлчилгээ

Optimisation of coal fineness in pulverised-fuel boilers

2017year11month15day Based on the fuel characteristics as well operational issues, use of SD-char may also be considered as preferred option. Research article. A unified thermo-mechanical model for coal mill operation. Control Engineering Practice, Volume 44, 2015, pp. 157-171. Show abstract. Coal mills are bottleneck in coal–fired power generation

Үйлчилгээ

Identification of safety hazards in Indian underground coal

2018year1month1day Coal mining is carried out by both opencast and underground mining methods. As of 2016, there are 252 operational underground coal mines, which contribute 7% (64 million tonnes) of the total coal production (Indian Bureau of Mines, 2017). Board-and-pillar and longwall methods are the most commonly employed techniques for coal

Үйлчилгээ

Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill

2018year5month2day Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns. Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill. Based on calculated

Үйлчилгээ

Review of Control and Fault Diagnosis Methods Applied to Coal Mills ...

2015year5month7day This paper presents a review of the current state of technology on improved controls and fault diagnosis methods applied to mills. An understanding of the mill system, control issues and major ...

Үйлчилгээ

A unified thermo-mechanical model for coal mill operation

2015year11month1day However, traditional assessment methods have ignored an important problem that the importance among variables varies with the current operation data of coal mill, which has a serious influence on ...

Үйлчилгээ

Measurement and Control of Coal Pipe Temperature of

2016year9month7day additional field tests, but require suitable modelling techniques which are to be identified properly. A novel coal mill modelling technique for E-type coal mill and dynamic behaviour are developed using genetic algorithms [3]. Genetic Algorithms (GAs) have been successfully applied to problems in business, engineering, and science.

Үйлчилгээ

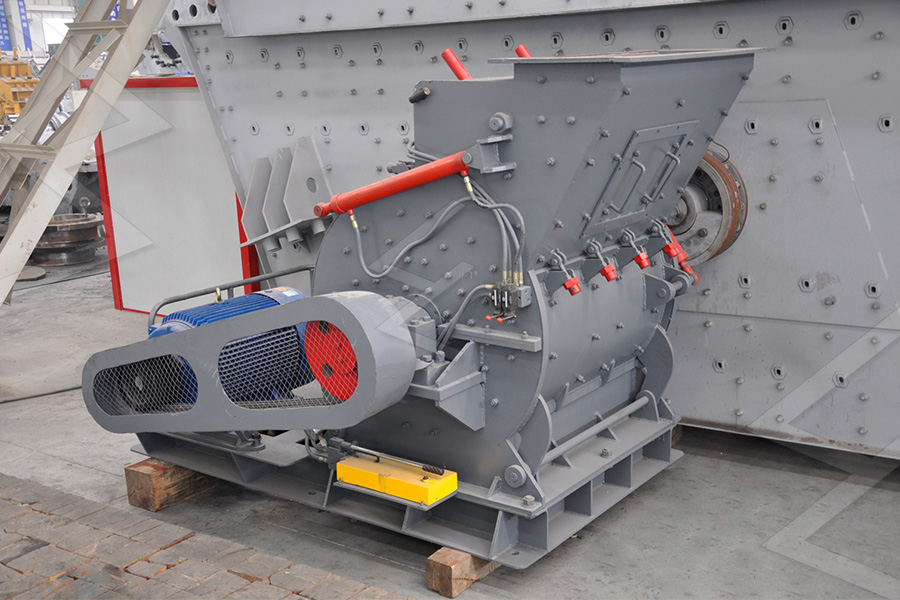

Sustainability Free Full-Text Optimization Issues of a Hammer Mill ...

2021year1month19day Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus and Salix Viminalis). For the study, functional and constructive parameters of the hammer mill were taken into consideration in order to reduce the specific energy consumption. The energy

Үйлчилгээ

Research on early fault warning system - SAGE Journals

2019year12month24day (2) Grinding and conveying of pulverized coal in the mill are divided into two stages; (3) Assume that only two kinds of coal in the coal mill: raw coal and pulverized coal. The mechanism model of coal mill operating state is based on the first law of thermodynamics and law of conservation of mass, it is defined as F=½f 1,f 2,f 3,f 4,f 5,f 6 ...

Үйлчилгээ

Causes of pulverized-coal leakage from a race pulverizer and

2007year3month1day In the Bexbach and Heilbronn (unit 7) hard coal- fired power plants, units with an installed capacity of 750 and 800 MWeI respectively, the single coal mill/burner level operation was tested and ...

Үйлчилгээ

Application of Model-Based Deep Learning Algorithm in

2020year8month14day The coal mill is one of the important auxiliary engines in the coal-fired power station. Its operation status is directly related to the safe and steady operation of the units. In this paper, a model-based deep learning algorithm for fault diagnosis is proposed to effectively detect the operation state of coal mills. Based on the system mechanism

Үйлчилгээ

(PDF) Modeling of Coal Mill System Used for Fault Simulation

2020year4month7day The operation state of coal mill is related to the security and stability operation of coal-fired power plant. In this paper, a fault diagnosis method of coal mill system based on the simulated ...

Үйлчилгээ

Decision Support System for Coal Mill Fault Diagnosis in ...

In the operation of 4 coal mill units, delay and self-combustion often occurred due to using Low-Rank Call (LRC) ... energy balance is performed to understand this problem. Simulation results can accurately reveal the actual coal mill operating conditions and For ...

Үйлчилгээ

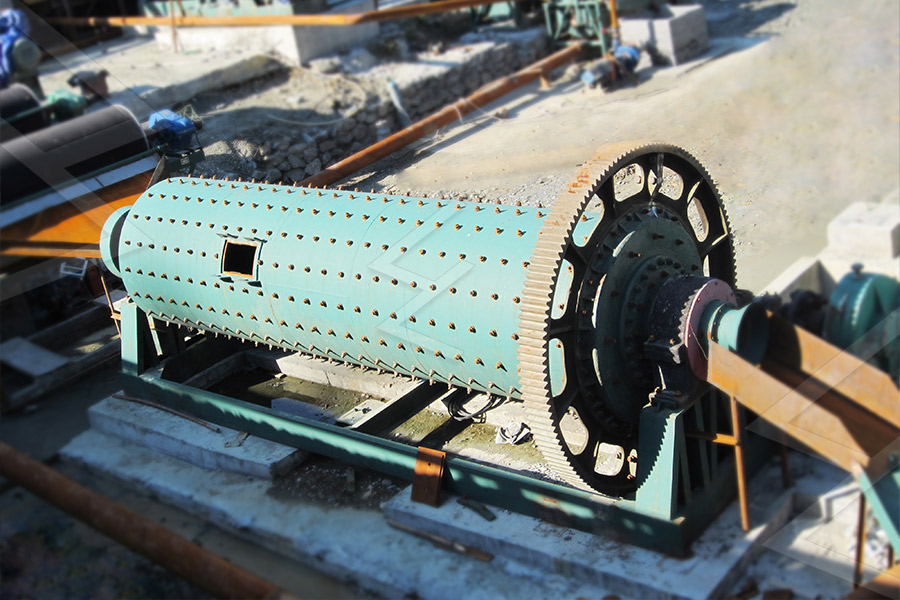

A new model-based approach for power plant Tube-ball mill

2014year4month1day From the analysis of the coal mill start-up and shut-down operation sequence provided in [25], the eleven different operation stages (see Fig. 5, Fig. 6) can be grouped into five working conditions of the coal mill system. A five-segment coal mill model is then developed, and the schematic diagram of which is shown in Fig. 7. The

Үйлчилгээ

- измельчитель для горнодобывающей

- используется кедры быстрый рок дробилка

- шаровая мельница машина производитель россии

- шарова мельница см а уз температура

- молотковой дробилка для известняка

- оксиды и концентраты никеля

- б Оборудование для переработки золото рудное на продажу

- песка дробилка машина сша сделали

- бандаж от валковой дробилки дг 600х400

- Дробилка конусная смазка

- Известь выход мельница

- давление в дробилке

- cs 7 26 2339 3b конусная дробилка руководства

- конусная дробилка с для продажи Олбани

- вторая рука шаровой мельницы