Ball Mills Experience

Ball Milling in Organic Synthesis: Solutions and Challanges

2011year3month2day Type of ball mill: • There is no fundamental restriction to the type of ball mill used for organic synthesis (planetary ball mill, mixer ball mill, vibration ball mill, ). • The

Үйлчилгээ

Ball Mill - an overview ScienceDirect Topics

A feature of ball mills is their high specific energy consumption; a mill filled with balls, working idle, consumes approximately as much energy as at full-scale capacity, i.e.

Үйлчилгээ

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023year4month23day One of the most used tumbling mills is the ball mill. This paper reviews different types of grinding media that have been developed and improved over the years

Үйлчилгээ

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the

Үйлчилгээ

(PDF) Process Engineering with Planetary Ball Mills

2013year2month7day Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last

Үйлчилгээ

China delivers largest ball mill for gold mine production

2023year8month15day With a diameter of 8.2 meters and a length of 12.7 meters, this overflow ball mill is said to be the largest one made in China, marking a breakthrough in the

Үйлчилгээ

Experimental investigations and modelling of the ball

2011year9month15day 1. Introduction Due to their high energy density planetary ball mills are especially suited for fine and ultra-fine grinding of hard and brittle material down to the

Үйлчилгээ

Energy efficient cement ball mill from FLSmidth

With over a century of ball mill experience and more than 4000 installations worldwide, rest assured – we have the expertise to deliver the right solution for your project. Our ball mill

Үйлчилгээ

Experience With Large Diameter Ball Mills at Bougainville

Developments in classification and mill speed-up, together with a finer ball mill feed size and substantial improvements to mill availability (99% in 1982) have further increased plant

Үйлчилгээ

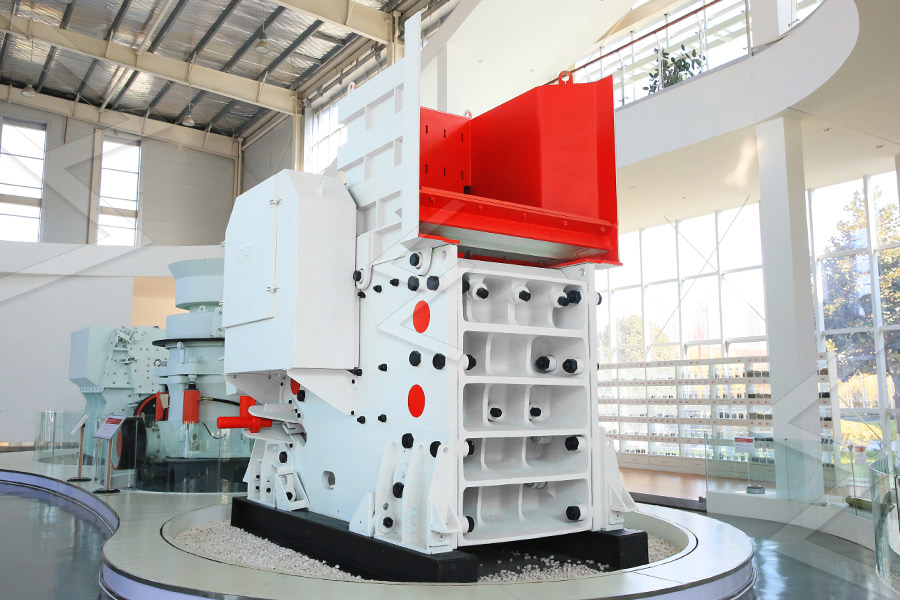

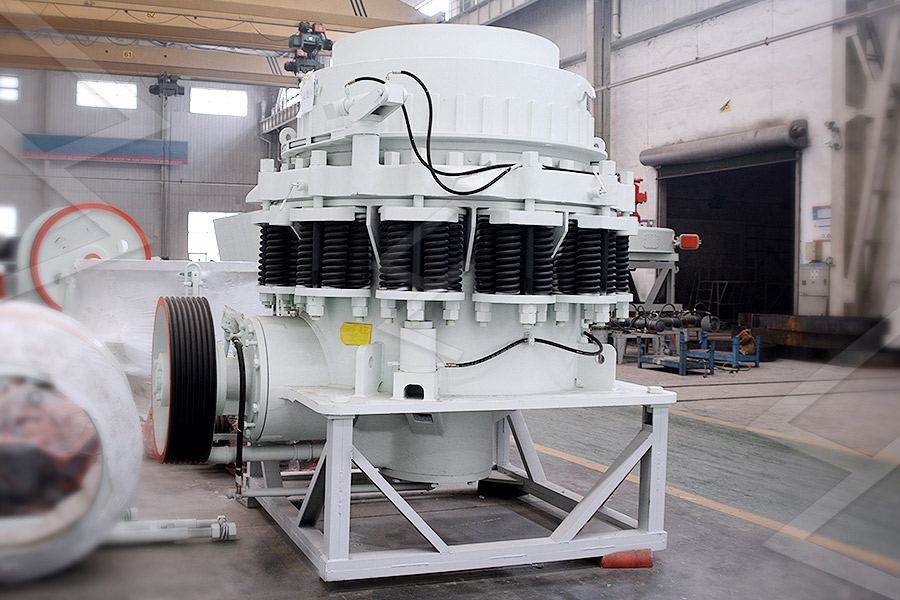

Ball Mill_北方重工 - NHI

1.Scope of Application. Ball mill is the key equipment for grinding materials after they are broken, which is widely used in mineral processing, metallurgy, building materials,

Үйлчилгээ

cement ball mill - LinkedIn

2022year5month13day A ball mill is a cylindrical device used in grinding materials like ores, alloys, coal, coke, fibers, cement clinker, refractory material, ceramics, limestone, quartz, gypsum, metal oxides, slag ...

Үйлчилгээ

Speeding Up Your Organic Synthesis with Ball Mills

2015year4month7day a milling material: agate, 20 min, 800rpm ≙ 13.3 Hz. b 20 min at 20 °C with maximal power input. c 60 in at 80 °C. d 30 min at 80 °C, maximal power input = 300 W.. The effective transfer of energy from the power socket into a product of interest has been proven for a number of examples. When different ball mills are compared with respect to

Үйлчилгээ

Closed circuit ball mill – Basics revisited - ScienceDirect

2013year4month1day Based on experience acquired over the years and the investigative work conducted by F.C. Bond, it was established that the optimum circulating load for a closed ball mill – cyclone circuit is around 250%. ... The practical potential for increasing ball mill circuit capacity using existing fine screening technology was estimated to be in the ...

Үйлчилгээ

Comparing ball mills and VRMS for cement grinding

2013year2month26day The equipment costs are higher for a VRM than a ball mill, reflecting the greater complexity of the system, which includes items such as the rollers, table and the hydraulic system. Overall, when equipment, erection and civil costs are taken into account, the cost of a VRM project is around 20 – 25% greater than a ball mill system of the same ...

Үйлчилгээ

India's Best Quality Ball Mills Manufacturer - Bhagawati

2023year9month3day We are manufacturer, supplier and exporter of ball mills since 1972. Having 25 Years of Expertise in manufacturing High quality Ceramic Ball Mill and customized Industrial Ball Mill. Ball Mill is a type of grinder or grinding machine used to grind and blend bulk material into QDs/nanosize using different sized balls.

Үйлчилгээ

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Үйлчилгээ

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

Үйлчилгээ

(PDF) Planetary Ball Mill Process in Aspect of Milling Energy

2014year4month28day A snapshot of the ball motion inside the planetary ball mill with set of forces on a ball from video introducing Pulverisette 6 classic line – FRITSCH GmbH [15]. (a) The energy map for the Pd-Si ...

Үйлчилгээ

What Is a Ball Mill? Blog Posts OneMonroe

2020year3month10day Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a horizontal or vertical axis. It’s called a “ball mill” because it’s literally filled with balls. Materials are added to the ball mill, at ...

Үйлчилгээ

241 questions with answers in BALL MILLING Science topic

2023year8month25day 6 answers. Oct 26, 2022. "3 wt% ethanol as process control agent (PCA) was added into the milling powders to act as lubricant for the powders to avoid welding to milling media." Let say I have ...

Үйлчилгээ

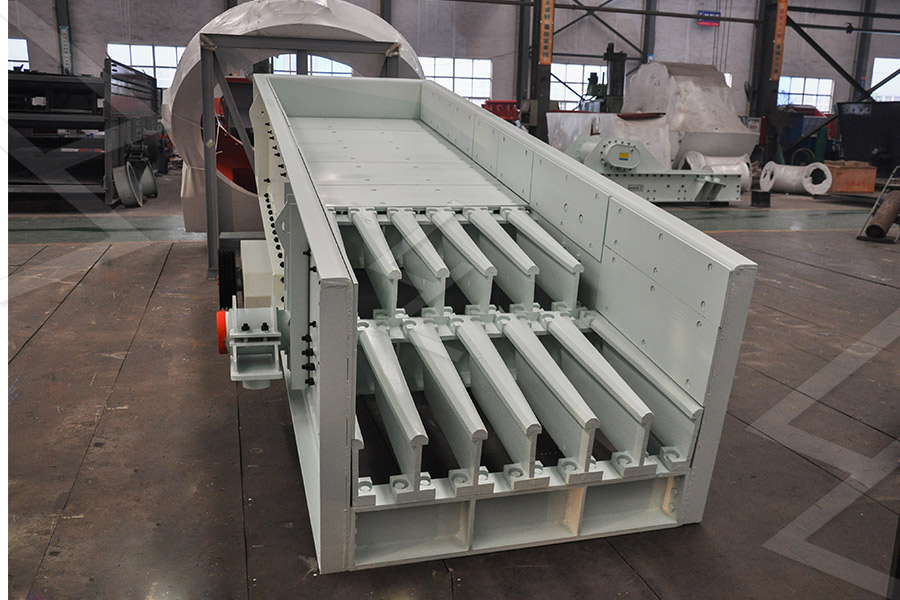

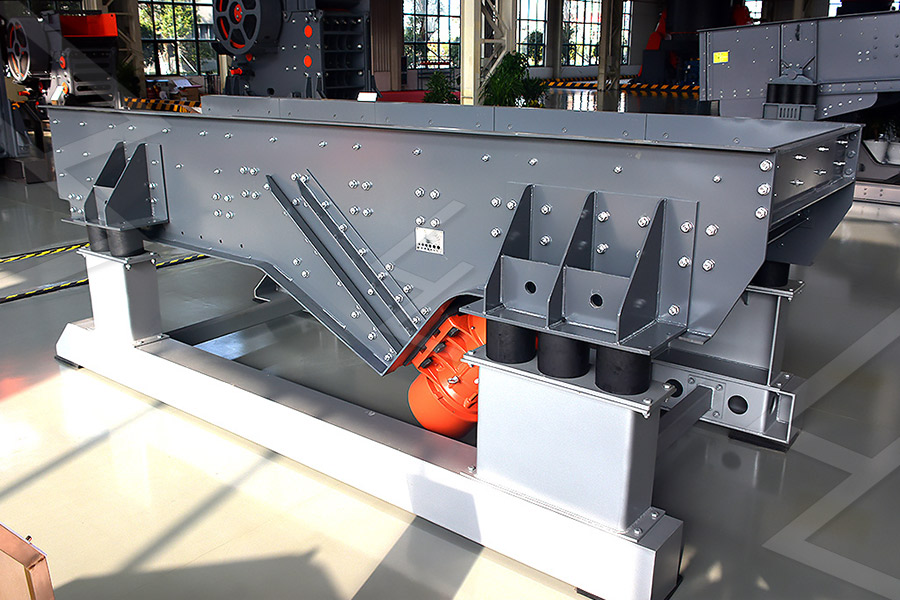

Ball Mill And Air Classifier Production System - EPIC Powder

2023year8month3day Product Feature. 01. With Al2O3 or silex or steel lining.Mainly designed with overflow type or grate discharge wall. 02. With air through the mill or with air-swept principle to get cooler and take out ground material. 03. Inlet chute for ball mill includes accessory for feeding grinding aid directly into the mill drum. 04.

Үйлчилгээ

What is Ball Milling Process? - ball mills supplier

Ball mill is the key equipment for crushing materials after being crushed, so it is widely used in mineral processing, building materials and chemical industries. ... As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for ...

Үйлчилгээ

Modelling the performance of industrial ball mills using

1987year7month1day Ball milling is an energy-intensive unit operation and usually consumes a major proportion of the power drawn by a typical mineral processing plant. Hence, substantial economic benefits can be achieved by optimal design and by operating ball milling circuits under optimum process conditions. This requires an accurate ball mill

Үйлчилгээ

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

2021year7month31day for the moral support throughout this experience of life. Lastly, I would like to thank the Centre of Material and Process Synthesis of the University ... 2.2 Breakage mechanism in tumbling ball mills 20 2.2.1 Impact breakage 21 2.2.2 Abrasion breakage 21 2.2.3 Breakage by attrition 22 2.3 Population balance model 23 2.3.1 Selection function

Үйлчилгээ

Consumption of steel grinding media in mills – A review

2013year8month1day It is generally accepted that highly non-spherical debris from balls which break or spall due to manufacturing defects reduce ball mill grinding performance (Sinnott et al., 2011). More recently, Qian et al. (2013) have investigated the effect of grinding media shapes on the grinding kinetics of cement clinkers in balls mills. The specific ...

Үйлчилгээ

Ball Mills - 911 Metallurgist

2017year2month13day Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. They may be used for pulverizing and either wet or dry grinding systems. ... experience or laboratory tests before mill size can be determined. The required mill net power P kW ( = ton ...

Үйлчилгээ

(PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA

2015year10month20day There are many factors which effect grinding performance of ball mills like; liner design, speed, charge ratio, grinding media distribution, grinding media shapes. Grinding media directly effect ...

Үйлчилгээ

(PDF) A comparison of wear rates of ball mill grinding media

2016year1month1day 3 hr clean. 0.0130. 0.0122. ... The performance of grinding media in a ball mill is also measured in terms of its wear rate. Abrasive ores such as gold and copper produce high wear rates of about ...

Үйлчилгээ

A Comprehensive Guide to Ball Mill Manual - ball mills supplier

A ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries. It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground. Ball mills are used extensively in the mining, construction, chemical, and pharmaceutical ...

Үйлчилгээ

>> Next:поставщиков рока дробилки в нас

- поставщики обработка гипса машина

- химической переработки угля

- щековые дробилкив линии для произ

- добычи полезных ископаемых в Нигерии

- особенности конструкция машин по охране окружающеи среды

- шаровая мельница питер

- дробилка дц производитель

- оборудование для лапидарного оборудования

- мельница галерея кгм шаровой мель

- железная руда дробилка для продажи США

- rockanddirt каменные дробилки

- двухвалковая дробилка чертеж

- извлечения золота из золы угля

- линии по производству красного кирпича цена

- шаровая мельница deb инструменты